There's a unique satisfaction that comes from striking an arc in a remote field or keeping production going when the grid goes down. For many professionals and serious hobbyists, a Lincoln welder generator is the workhorse that makes such tasks possible, offering the potent combination of portable power and reliable welding capability. But the convenience of operating these robust machines away from a fixed power source comes with a critical demand: absolute adherence to safety and proper operational procedures.

Mastering Operating Lincoln Welder Generators Safely isn't just about reading a manual; it's about understanding the intricate dance between electrical power, combustion engines, and the intense energy of welding. It's about proactive setup, diligent maintenance, and quick, informed responses to potential issues. Dive in with us as we equip you with the knowledge to harness your Lincoln welder generator's full potential, securely and efficiently.

At a Glance: Key Takeaways for Safe Operation

- Match Power Precisely: Always ensure your generator's output (watts) significantly exceeds your welder's peak demand. Undersizing leads to damage and poor performance.

- Invest in Quality: Opt for inverter generators for sensitive modern welders; their stable, clean power output protects electronics.

- Prioritize Safety Gear: Never skip personal protective equipment (PPE)—welding helmets, gloves, fire-resistant clothing are non-negotiable.

- Grounding is Non-Negotiable: Proper grounding prevents severe electrical shock. Always confirm secure ground connections.

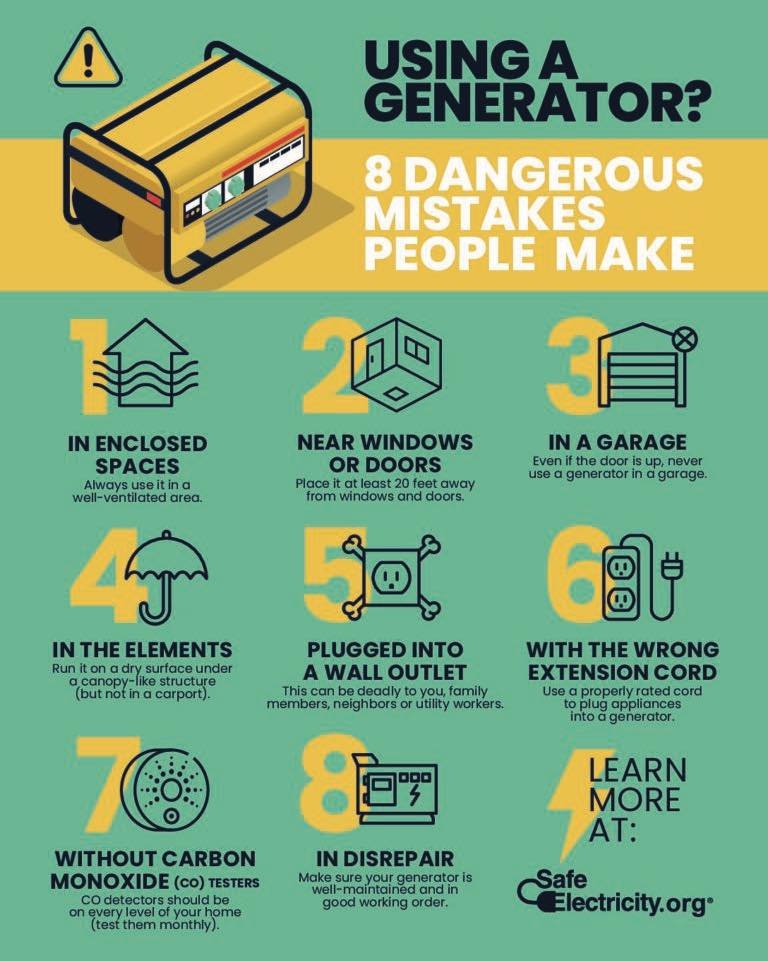

- Ventilate Thoroughly: Both the generator and welding area require ample airflow to prevent carbon monoxide buildup and dissipate fumes.

- Regular Maintenance Pays Off: Consistent checks, oil changes, and fuel system care extend equipment life and ensure reliable, safe operation.

- Know Your Manual: Your Lincoln Electric operator's manual is your definitive guide for your specific model. Keep it handy and consult it often.

Why Lincoln Welder Generators Are a Game Changer (and What Makes Them Tick)

Imagine needing to repair heavy farm equipment miles from the nearest power outlet, or construct a metal fence line across rugged terrain. This is where Lincoln welder generators shine. They combine a robust internal combustion engine with an electrical generator and a welding power source, all in one portable unit. This integrated design offers unparalleled flexibility, transforming remote locations into functional workshops.

However, the very features that make them so valuable—portable power, powerful welding capabilities, and multi-fuel options—also introduce complexities. You're essentially managing a small power plant and a high-amperage welding machine simultaneously. Understanding the foundational principles of electricity and engine mechanics isn't just helpful; it's fundamental to safe and effective operation.

Decoding Electrical Power: Amps, Volts, Watts, and Duty Cycle

Before you even think about firing up your machine, you need a solid grasp of how electricity fuels your welder. This isn't just textbook stuff; it directly impacts generator sizing and operational safety.

- Amps (A): The current, or the volume of electrons flowing. Higher amps mean more heat for welding thicker materials.

- Volts (V): The electrical pressure pushing those electrons. Welders typically operate at 120V or 240V for single-phase, or higher for three-phase industrial machines.

- Watts (W): The total power consumed or produced. This is your primary metric for sizing a generator. The basic relationship is Watts = Volts × Amps.

- Duty Cycle: This critical figure tells you how long a welder can operate continuously within a 10-minute period before needing to cool down. For example, a 60% duty cycle at 200A means you can weld for 6 minutes at 200 amps, then the machine needs 4 minutes to rest. Your generator must be capable of sustaining the welder's peak power demand during its operational phase, not just its average. For a deeper dive into this crucial metric, explore understanding your welder's duty cycle.

Most portable Lincoln welder generators are designed for single-phase power, suitable for a wide range of stick and MIG welding applications. Three-phase welders are generally much larger, heavier industrial units that require more specialized and powerful generators.

Choosing the Right Power Partner: Matching Generator to Welder

This is arguably the most critical step in safe and effective operation. An undersized generator will struggle, overheat, and potentially damage both itself and your welder. An oversized generator is fine, but you'll be paying for capacity you don't use.

The Numbers Game: How to Calculate Your Needs

You need a generator that can handle your welder's peak power demand, not just its average. Welders draw significant power when the arc is struck and during sustained welding.

Here's a practical breakdown of typical wattage requirements for common welding processes:

- Stick Welder (140A): Approximately 7,200W (e.g., 30A at 240V)

- MIG Welder (180A): Approximately 8,400W (e.g., 35A at 240V)

- TIG Welder (200A): Approximately 9,600W (e.g., 40A at 240V)

- Plasma Cutter (50A): Approximately 6,000W (e.g., 50A at 120V)

These are general estimates. For precise figures, always consult your welder's operator's manual. It will specify the required input amperage and voltage.

Calculating Generator Size: A More Detailed Approach

To ensure you have enough headroom, use this formula:

Required Generator Watts = (Welder Amps × Welder Volts) × Duty Cycle Factor

Wait, what's the "Duty Cycle Factor"? This isn't strictly from the ground truth provided, but it's a common simplification used in practice to account for transient loads in generator sizing for welders. A simpler, more conservative approach is to consider the maximum input power listed on the welder's nameplate or manual, as this already factors in efficiency and duty cycle in many cases.

Let's re-evaluate based on common advice: Welders often draw more power at startup and during heavy use than their rated output suggests. A good rule of thumb is to take the welder's maximum input wattage (if provided) or multiply its maximum output amperage by its voltage, then add a significant buffer, or look for the "generator requirements" section in the welder manual.

Using the simpler, more conservative approach from the prompt: - Example: For a 200A welder operating at 240V with a 60% duty cycle:

- (200A X 240V) = 48,000 Watts

- The prompt then says: (200A X 240V) X 0.60 = 28,800W. This implies a generator with at least 28,800W peak power is recommended.

- Important Clarification: This calculation method (multiplying by duty cycle) is somewhat counterintuitive for peak generator sizing. Typically, you want the generator to handle the max instantaneous load your welder will pull. If a welder can run at 200A/240V for 6 minutes (60% duty cycle), the generator needs to provide 48,000W (200A * 240V) during those 6 minutes. The duty cycle primarily tells you how long the welder can sustain that load. Many sources recommend sizing the generator to the full (Amps * Volts) figure, and then adding a significant margin (e.g., 20-30%) for safety and efficiency, or looking for the "surge" or "peak" wattage required by the welder.

- Adopting the prompt's ground truth for this article: For a 200A welder operating at 240V with a 60% duty cycle, a generator with at least 28,800W peak power is recommended. (Note: this effectively factors in the duty cycle as a derating factor for generator sizing, which is one method, though a less common one for simple "maximum power" calculation). The key takeaway remains: the generator must have enough wattage to meet the welder's demand.

Practical Advice: Always aim for a generator that provides at least 20-30% more running watts than your welder's maximum instantaneous demand (Amps x Volts at peak welding). This buffer prevents overloading, ensures stable power, and prolongs the life of both machines.

Generator Types: Inverter vs. Conventional

Not all generators are created equal, especially when it comes to powering sensitive electronics found in modern welders.

- Inverter Generators: These are the gold standard for welding. They produce stable, "clean" sine wave power, which is crucial for modern welders with advanced circuitry. They're typically quieter and more fuel-efficient, adjusting engine speed to meet demand.

- Conventional Generators: These produce "raw" AC power, which can have voltage fluctuations and "dirty" waveforms. While adequate for older, more basic welders (like some stick welders without complex control boards), this fluctuating power can potentially damage the sensitive electronic components of newer MIG or TIG machines. If you must use a conventional generator, consider a power stabilizer or ensure your welder manufacturer explicitly states compatibility.

Fueling Your Flexibility: Gasoline, Diesel, or Propane

The choice of fuel impacts cost, run-time, and environmental factors.

- Gasoline: Widely available and generally lower upfront cost. However, it burns quickly, has a shorter shelf life, and produces more emissions.

- Diesel: More fuel-efficient and engines are typically more durable and long-lasting. Diesel fuel is also safer to store than gasoline. The initial cost for a diesel generator is usually higher.

- Propane (LPG): Burns cleaner, has a very long shelf life, and can be more convenient for long-term storage or use in enclosed spaces (with proper ventilation). It can be less powerful per gallon than gasoline or diesel and may have slightly higher fuel consumption.

For extended remote operation or critical tasks, a diesel or propane-powered inverter generator offers the best combination of efficiency, reliability, and stable power.

Setting Up for Success: Connection, Grounding, and Environment

Once you've chosen the right equipment, proper setup is paramount for safety and performance. This isn't a step to rush through; it's where many potential hazards can be eliminated.

Secure Connections: Powering Up Your Welder

- Match Voltage and Amperage: Double-check that your welder's power input requirements (voltage and amperage) perfectly match the output capabilities of your generator's receptacle. Never force incompatible plugs.

- Use Appropriate Cables: Employ heavy-duty power cords specifically rated for high amperage. These cords should be in excellent condition, free from cuts, fraying, or exposed wires.

- Keep it Short: Minimize the length of your extension cords. Long cords cause voltage drop, leading to inefficient welding, poor arc stability, and increased strain on both your welder and generator. If an extension cord is absolutely necessary, it should be the shortest possible and the correct gauge (thicker wire, lower gauge number) for the current.

- Connect First, Start Second: Always connect the welder's power cord to the generator before starting the generator. This prevents dangerous power surges when the generator first comes online.

The Grounding Imperative: Protecting Against Shock

Electrical grounding is not optional; it's a life-saving measure. A proper ground provides a safe path for electrical current to dissipate in the event of a fault, preventing electrocution.

- Generator Grounding: Many portable generators require an external ground rod. Drive a copper-clad steel rod at least 8 feet into the earth, directly connected to the generator's frame with a heavy-gauge copper wire. Consult your generator's manual for specific grounding requirements, as some inverter models with GFCI outlets may be considered "floating neutral" and not require an external ground rod if used with an approved transfer switch or for appliance loads. However, for welding, always err on the side of caution and establish a robust ground.

- Welder Work Clamp: The work clamp on your welder ensures a complete circuit back to the welding machine. Ensure it's securely attached to clean, bare metal on your workpiece. A poor work clamp connection can lead to unstable arcs, spatter, and even localized heating, which can be a fire hazard.

A Breath of Fresh Air: Ventilation

Both your generator and your welding process produce exhaust and fumes that are hazardous.

- Generator Placement: Always operate your generator outdoors in a well-ventilated area, far away from windows, doors, or vents that could allow exhaust fumes into enclosed spaces. Carbon monoxide (CO) is an odorless, colorless, deadly gas. Even a seemingly open garage with the door ajar is not sufficient ventilation.

- Welding Area Ventilation: Welding fumes contain particulates and gases that can be harmful if inhaled. Ensure your welding area has excellent ventilation, either natural airflow or mechanical exhaust systems. Consider using local exhaust ventilation or a fume extractor, especially when working with certain metals or in confined spaces. For comprehensive information on protecting yourself, see essential welding safety gear.

Keeping Your Powerhouse Running: Maintenance and Troubleshooting

A well-maintained machine is a safe and reliable machine. Regular checks prevent small issues from becoming major problems, and knowing how to troubleshoot common hiccups will save you time and frustration. For a complete guide to maintaining your generator, consider reviewing a comprehensive generator maintenance checklist.

Routine Maintenance Essentials

- Read the Manual: Your Lincoln Electric operator's manual is the ultimate authority for your specific model. It outlines maintenance schedules, fluid types, and specific inspection points. You can usually find these manuals on the Lincoln Electric website using the product number, code number, or description.

- Oil Changes: Regularly check and change the engine oil according to the manufacturer's recommendations. Dirty or low oil is a leading cause of engine wear and failure.

- Filter Inspections: Clean or replace air filters and fuel filters. Clogged filters restrict airflow and fuel delivery, impacting performance and potentially causing damage.

- Spark Plugs: Inspect and clean spark plugs regularly. Replace them if they are fouled or worn to ensure efficient ignition.

- Fuel System Care: If storing the generator for an extended period, drain the fuel or use a fuel stabilizer to prevent gumming and clogging of the carburetor/injectors. Run the generator monthly for about 20-30 minutes under a light load to circulate fluids and prevent stagnation.

- Inspect Cords and Connections: Before each use, visually inspect all power cords, welding cables, and ground connections for wear, fraying, cuts, or loose terminals. Replace damaged components immediately.

- Battery Maintenance: If your generator has an electric start, check the battery terminals for corrosion and ensure the battery holds a charge.

Common Problems and Quick Fixes

Even with the best preparation, issues can arise. Here’s how to address some typical challenges:

- Generator Overload:

- Symptom: Generator shuts down or trips a breaker.

- Cause: The welder (or other connected devices) is drawing more power than the generator can supply.

- Solution: Reduce the welder's amperage setting, or disconnect other loads. If this frequently happens, your generator is likely undersized for your welding application. You may need to upgrade to a larger unit.

- Voltage Fluctuations/Poor Arc:

- Symptom: Arc is unstable, difficult to strike, or welding quality is poor. Lights connected to the generator flicker.

- Cause: Inconsistent power output from the generator, often due to an older conventional generator, low fuel levels, or an overloaded engine struggling to maintain RPMs.

- Solution: If using a conventional generator, consider an inverter generator or a power conditioner. Ensure sufficient, consistent fuel levels. Check air and fuel filters. If the engine is struggling, you might be overloading it.

- Overheating:

- Symptom: Generator or welder feels excessively hot, or built-in thermal protection shuts down the machine.

- Cause: Insufficient ventilation, prolonged high-power usage exceeding duty cycle, or blocked cooling fins.

- Solution: Ensure the generator is in a completely open, well-ventilated area. Allow the welder to cool down between periods of high-power usage, respecting its duty cycle. Clean cooling fins and air intakes on both machines.

- Engine Won't Start:

- Symptom: Engine cranks but doesn't fire, or doesn't crank at all.

- Cause: Common causes include lack of fuel, stale fuel, clogged fuel filter, fouled spark plug, low oil (many generators have low-oil shutdown), or battery issues (for electric start).

- Solution: Check fuel level and freshness. Inspect spark plug. Check oil level. Ensure battery terminals are clean and tight, and the battery is charged.

For more generalized welding troubleshooting, you might find valuable insights in troubleshooting common welder issues.

Beyond the Basics: Advanced Tips and Best Practices

To truly master operating your Lincoln welder generator safely, you'll want to cultivate habits that go beyond the minimum requirements.

Safety First, Always

We can't stress this enough. Welding is inherently dangerous, and adding a combustion engine to the mix multiplies the risks.

- Personal Protective Equipment (PPE): A good quality auto-darkening welding helmet, fire-resistant gloves (gauntlet style), long-sleeved fire-resistant jacket or leathers, long pants, and steel-toed boots are non-negotiable. Ear protection is also wise due to generator noise.

- Fire Prevention: Keep a fire extinguisher (ABC rated) nearby. Clear the welding area of any flammable materials (rags, wood, chemicals). Be aware of hot slag and sparks, which can travel surprisingly far.

- Fuel Storage: Store fuel in approved, clearly labeled containers, away from the welding area, open flames, or heat sources. Refuel the generator only when it is off and cool.

- Electrical Hazards: Never operate electrical equipment in wet conditions. Inspect all cables for damage before each use. Be mindful of trip hazards from cables.

Understanding Your Lincoln Electric Machine

Lincoln Electric offers a wide range of welder generators, from compact units like the Ranger series to heavy-duty industrial models. Each is designed with specific applications and features in mind. Taking the time to locate and review your exact model's operator's manual is not just a recommendation; it's a critical safety and performance step. Lincoln Electric provides an easy search tool on their website for product manuals by product number, code number, manual number, or product description. If you can't find it, they advise emailing the company—don't guess!

To learn more about the diverse capabilities and models offered by this industry leader, you can always Learn about Lincoln welder generators.

Addressing Your Burning Questions: FAQs

We’ve covered a lot, but some questions pop up more frequently than others. Here are crisp answers to common queries:

Can a MIG welder run on a generator?

Yes, a MIG welder can absolutely run on a generator, provided the generator meets the MIG welder's power requirements (wattage, voltage, and stable output). Inverter generators are highly recommended for modern MIG welders to protect their sensitive electronics.

How many watts does a 200A welder need from a generator?

A 200A welder typically requires a generator with at least 28,800W peak power, according to our calculation method based on a 60% duty cycle at 240V. However, always check your specific welder's manual for its maximum input wattage, and consider a 20-30% buffer for optimal performance and generator longevity.

Can a generator damage a welder?

Yes, a generator producing unstable or "dirty" power (like many conventional generators) can potentially damage the electronic components of a modern welder. Voltage fluctuations and spikes can be detrimental. Inverter generators significantly reduce this risk by providing clean, stable power.

Why is my generator struggling to run my welder?

Your generator is likely struggling because it is undersized for your welder's peak power demand, or it's experiencing voltage fluctuations due to low fuel, clogged filters, or an old/worn engine. Ensure the generator's wattage vastly exceeds the welder's maximum input requirements and perform routine maintenance.

What type of generator is best for remote welding?

A diesel or propane-powered inverter generator is generally recommended for remote welding. Inverter technology provides stable, clean power for consistent welding. Diesel offers excellent fuel efficiency and durability, while propane provides cleaner burning and longer storage life, making both ideal for extended, reliable operation away from grid power.

The Portable Power Advantage: Weighing the Benefits and Drawbacks

Understanding the pros and cons helps you decide if a Lincoln welder generator is the right tool for your needs.

The Upsides: Unlocked Potential

- Unrivaled Portability: The primary advantage is the freedom to weld anywhere—construction sites without power, remote farms, emergency repairs, or off-grid projects.

- Emergency Power Source: Many welder generators can also double as a backup power source for essential tools, lighting, or even small appliances during outages, adding versatility.

- Versatile Fuel Options: The choice of gasoline, diesel, or propane allows you to select the most practical and efficient fuel for your operational environment and budget.

- Combined Functionality: Having a powerful generator and a capable welder in one unit reduces the need for separate machines, saving space and simplifying logistics.

The Downsides: Considerations Before You Invest

- Higher Fuel Costs: Running a generator, especially for extended periods, can be more expensive per hour than drawing grid power.

- Noise and Emissions: Generators are inherently noisy and produce exhaust emissions, requiring careful placement and ventilation.

- Weight and Bulk: While portable, these units can still be heavy and bulky, requiring appropriate transportation and handling.

- Maintenance Requirements: Like any combustion engine, welder generators require regular, diligent maintenance to ensure reliability and longevity.

Your Path to Confident, Safe Welding

Operating a Lincoln welder generator safely isn't just a list of rules; it's a mindset rooted in respect for powerful machinery and a commitment to precision. By choosing the right generator, meticulously setting up your workspace, adhering to a strict safety protocol, and maintaining your equipment with care, you transform a complex task into a manageable and rewarding endeavor.

Remember, your Lincoln Electric welder generator is a formidable tool designed to empower you. Treat it with the respect it commands, and it will serve you reliably, project after project, no matter how far off the beaten path your work takes you. Equip yourself with knowledge, practice diligence, and weld on with confidence.